15% introductory discount until the end of February 2026:

Maykestag Speedtwister+ ALU

High-performance milling cutter for demanding machining operations in aluminum or non-ferrous metals.

Perfect for trochoidal milling strategies.

Exclusive introductory discount for our Swiss customers until the end of February 2026!

Our field service colleagues will be happy to advise you personally on site.

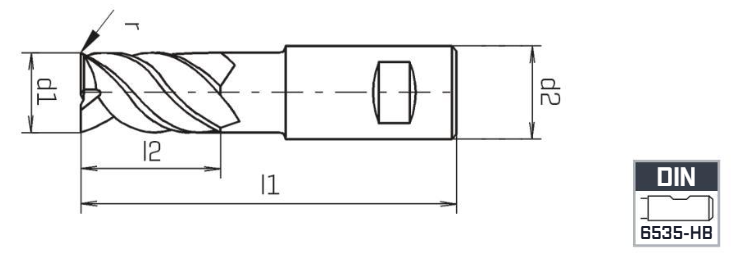

| Speedtwister+ 5xD | Introductory discount 15% | d1 h10 mm | d2 h6 mm | l1 mm | l2 mm | r mm | Z | |

| 6176 060 Ø6.00 | CHF 70.40 | CHF 59.84 | 6 | 6 | 72 | 32 | 0.10 | 4 |

| 6176 080 Ø8.00 | CHF 106.80 | CHF 90.78 | 8 | 8 | 83 | 42 | 0.15 | 4 |

| 6176 100 Ø10.00 | CHF 139.00 | CHF 118.15 | 10 | 10 | 99 | 52 | 0.15 | 4 |

| 6176 120 Ø12.00 | CHF 182.20 | CHF 154.87 | 12 | 12 | 115 | 62 | 0.20 | 4 |

| 6176 160 Ø16.00 | CHF 315.50 | CHF 268.18 | 16 | 16 | 140 | 82 | 0.25 | 4 |

| 6176 200 Ø20.00 | CHF 504.00 | CHF 428.40 | 20 | 20 | 163 | 102 | 0.35 | 4 |

Milling aluminum presents certain difficulties

Aluminum places special demands on the tool: its high ductility and tendency to form built-up edges make machining difficult.

Short service life & unstable quality

Without specifically adapted tools, these material properties lead to reduced wear protection and unstable machining processes. The result is shorter tool life and reduced process reliability.

But there is a solution

The Speedtwister+ ALU, characterized by its extra-long design, four cutting edges, unequal helix pitch and internal cooling, is the ideal trochoidal high-performance milling cutter for aluminium and non-ferrous metals. The milling cutter covers the entire range of applications, from softer wrought and cast alloys to high-strength, difficult-to-machine aluminum or non-ferrous alloys.

Key benefits and technical details:

- Increased tool life: The specially developed combination of optimized cutting edge geometry, polished functional surfaces and coordinated coating ensures efficient chip removal, reduced wear and a significantly extended tool life. This ensures maximum cost-effectiveness and high process reliability.

- Heat management: Thanks to the high surface quality and central internal cooling, heat is effectively dissipated. This prevents built-up edges and guarantees stable machining processes even at high cutting speeds.

- Performance: The innovative geometry results in lower radial cutting forces and allows higher axial infeeds, which enables high cutting performance. The milling cutter is also characterized by excellent running smoothness and optimum chip removal.

- Application strategies: The tools support a wide variety of milling strategies in aluminum and non-ferrous metals and can be used in different machining situations without great effort. They are suitable for both static and dynamic machining, especially for trochoidal milling (HPC).