In the stranglehold of the market - when cost pressure becomes a daily reality

The automotive industry is undergoing the most profound change in its history. New technologies, changing customer needs and the rapid rise of global competitors are intensifying the battle for market share. A fight that shows no mercy.

Price pressure is increasing. Margins are shrinking. The competition never sleeps.

In this highly tense environment, it is not only the vehicle manufacturers themselves who are under pressure. The challange is being consistently passed on to the next stage of the value chain: the suppliers. What were once long-term partnerships are increasingly reduced to cold numbers-games. Those who do not produce more efficiently, more cost-effectively and faster run the risk of being replaced.

For many suppliers, this means working at the limit every day.

Cost reduction is no longer simply a goal, it becomes a survival strategy. Every process is scrutinized, every second of running time is optimized, every gram of material is calculated. Innovations no longer steems from curiosity, but it springs from necessity.

Practical example

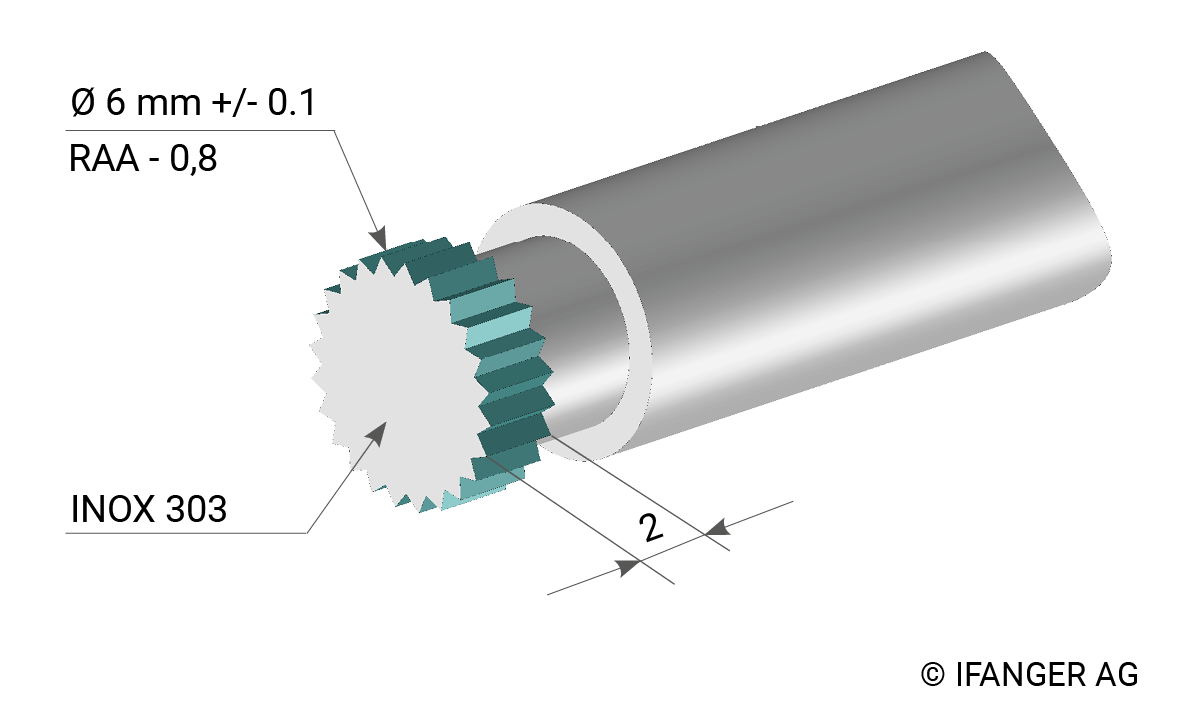

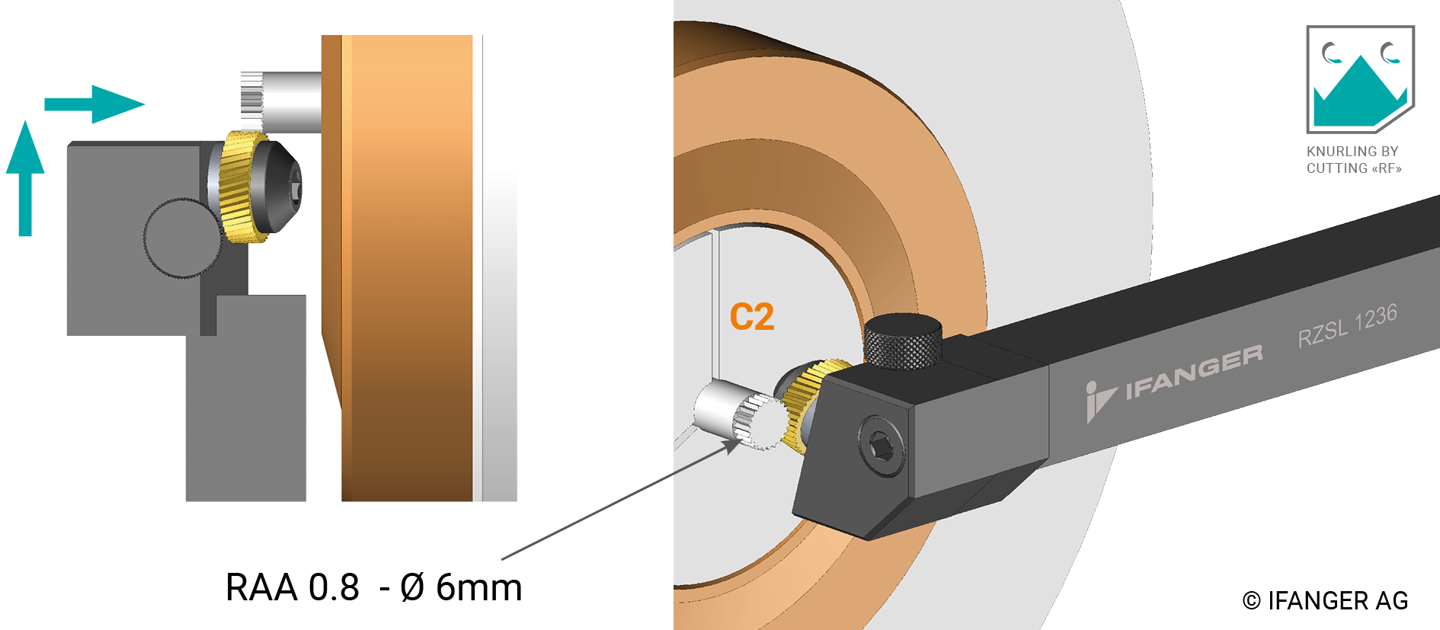

The following case illustrates how a contract manufacturer successfully mastered these challenges for a specific component. For a renowned vehicle manufacturer, he produces large quantities of slim, long precision rods that are used in manual gear-boxes. Production is carried out on a STAR CNC Swiss-type lathe (model SB16), which is specially designed for the machining of high-precision and complex workpieces. Round bars made of Inox 303 with a diameter of 6 mm are used as the starting material. A straight knurled profile (RAA) with a pitch of 0.8 mm is produced at the end face of the rod - in accordance with the drawing specification below. The customer places high demands on the quality of the knurl: every single tooth must be precisely formed and visually flawless.

Initial situation and changed conditions

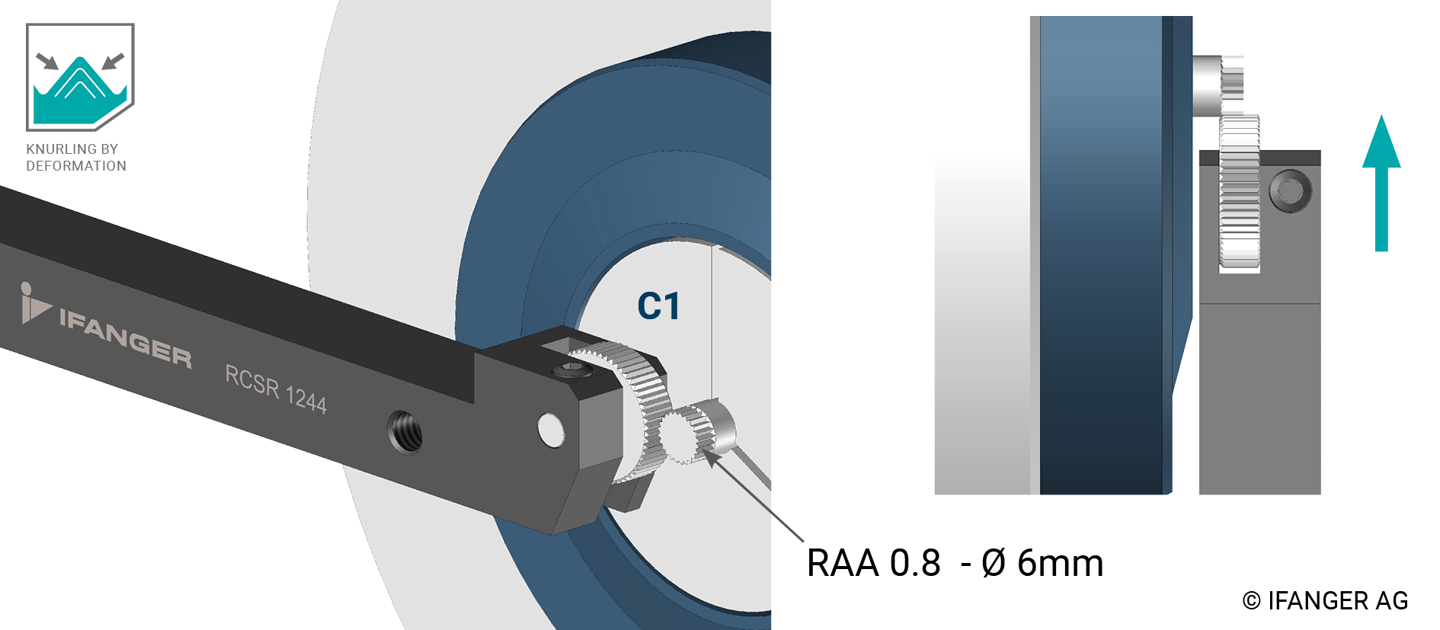

Since the start of production many years ago, the knurled profile (RAA 0.8) has been applied to the workpiece using the knurling process by deformation. This is a cold forming process in which the material is brought into the desired shape without removing chips. When only a single knurling roll is used, extremely high radial forces are generated, acting directly on the workpiece. Such forces can overstress the machine or bend the workpiece undesirably - especially if it protrudes far out of the collet. As the machining is carried out on the main spindle (C1) of the Swiss-type lathe lathe, the combination of machine and tool proved to be ideal for this application: The knurled profile could be produced reliably, with high repeat accuracy and in large quantities.

However, the massive cost and deadline pressure required new solutions. The cycle times per workpiece had to be reduced by 30% without any increase in tool costs.

Solution 1: Knurling on the counter spindle with two knurling rollers

To achieve a 30% reduction in machining time the knurling operation had to be shifted from the main machine spindle (C1) to the counter spindle (C2). As the counter-spindle offers lower clamping forces and limited X-axis feed force compared to the main spindle, knurling had previously only been used on the main spindle. To counteract the problem of high radial forces, the concept of the double knurling rolls fork-holder was developed in collaboration with several users. This tool concept largely neutralizes the forces generated during knurling, so that only low loads occur in the X-direction - significantly less than with the classic single knurling roll process.

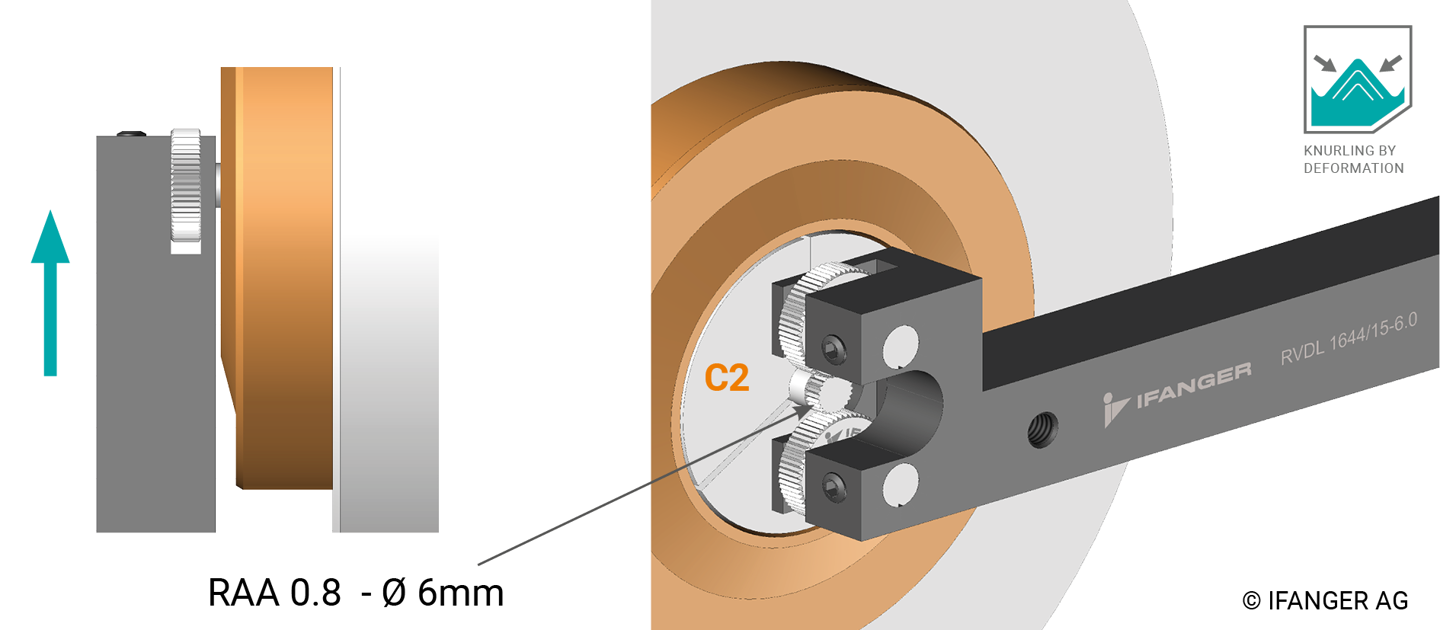

Solution 2: Knurling on the counter spindle with a roller

The first solution enabled a 30% reduction in cycle time and significantly reduced radial forces. However, due to the high demands on the surface quality of the knurl and the tight diameter tolerances, an even further improved solution was required. For this purpose, the knurling process was shifted from knurling by deformation to knurling by cutting. This process offers advantages for applications with high demands on the surface aesthetics and dimensional accuracy of the knurl profile.

The result is impressive: surface quality, tooth geometry and dimensional accuracy of the knurl are achieved reliably and in outstanding quality. In addition to the 30% cycle time reduction, tool costs have also been significantly lowered. The knurling roll is also double-edged, easily reversible and can be reused, which further increases tool life and reduces costs.

WORKPIECE

Material: INOX 303 (1.4305)

Knurl shape: DIN82-RAA-0.8

Knurl diameter: 6 mm

Knurl width: 2 mm

KNURLING TOOLS

Knurling holder: IFANGER RZSL 1236 > e-shop

Knurling roll: RFBL-110306-15-0.8-TIN > e-shop

Cutting values: n=1000 rpm, f=0.05 mm in Z-direction

Machining time per knurl: 6 sec.

Further helpful information can be found in the catalog

Whether left-hand or right-hand applications - our holders and knurling rolls are available in numerous standard designs and sizes and fit all standard Swiss-type and CNC lathes.