High-performance milling of Grade 5 titanium!

Grade 5 titanium, also known as Ti-6Al-4V, is one of the most commonly used titanium alloys. Due to its high strength, low weight, resistance to high temperatures and fatigue, and biocompatibility, it is the preferred choice for use in medical technology, the watch industry, and aerospace.

The three saboteurs in titanium machining

1. Extreme heat at the cutting edge

Titanium is a very poor heat conductor. Around 80% of the heat generated remains directly at the cutting edge of the tool. This causes the temperature at the point of contact to rise sharply. The material also tends to cold welding, meaning that under high thermal and mechanical stress, titanium bonds with the cutting material. The consequences are greatly accelerated tool wear, significantly reduced service life, and correspondingly higher tool costs.

2. Dangerous Springback effect

Due to its low modulus of elasticity, titanium springs back behind the cutting edge. This results in dimensional deviations, scrap, and unstable production processes.

3. Out-of-control long chips

When milling, turning, or drilling grade 5 titanium, tough, long chips are produced that wrap around the tool or even the chuck. Tangled chip structures cause blockages in the workpiece, fill the machine room, and severely impede chip removal. Without active chip control measures, every machining step becomes a nightmare.

These three “saboteurs” lead to increased wear, higher risk, and reduced process reliability. Only with targeted and well-thought-out measures, in particular controlled chip formation, efficient cooling, and sharp tool cutting edges, can the machining process remain stable, safe, and economical.

Problems from a practical case study

A large, cubic aircraft component made of grade 5 titanium measuring 600 × 600 × 600 mm caused considerable problems during roughing with a standard Ø12 mm end mill. The difficulties manifested themselves in uncontrollably long and tangled chips, pronounced built-up edges on the cutter, and very short tool life. In addition, it was found that the use of cutters not designed for titanium can lead to micro-chipping. All this resulted in constant manual intervention and frequent tool changes; unmanned production during the night shift was not possible. In addition, high tool costs and unpredictable machine stoppages arose, which further burdened the entire process.

The profit-making solution

To solve the problems, the customer tested different brands of milling cutters as well as various cutting parameters and coolant supply variants, but did not achieve satisfactory results overall, especially in terms of process reliability and tool life.

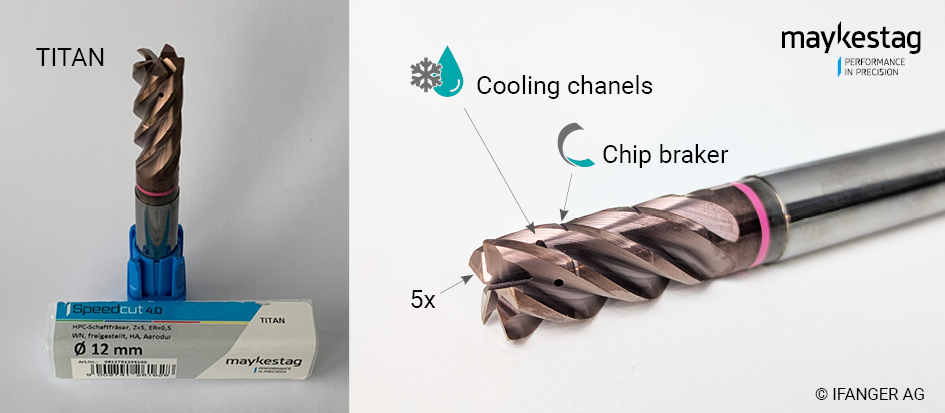

It was only when the customer used the MAYKESTAG TITANIUM milling cutter from the Speedcut 4.0 family, which was specially developed for milling titanium alloys, that they found the long-awaited solution. The key features of the milling cutter that contributed to its success include a cutting edge geometry tailored to titanium with an uneven helix angle and five cutting edges. On top of that, integrated chip breakers directly on the very sharp cutting edges, efficient internal cooling channels and an innovative high-performance coating.

Key data for the case study

Material

Grade 5 titanium

Workpiece dimensions

600 x 600 x 600 mm

Industry

Aircraft industry

Milling cutter

MAYKESTAG TITANIUM milling cutter / Speedcut 4.0 - Item 0812701205100

Radius = 0.5 – Diameter = 12 mm

Integrated chip breakers

Integrated radial coolant channels

Cutting values

Spindle speed (n) = 2,388 rpm

Feed rate (Vf) = 636 mm/min

Ap = 14.2 mm

Ae = 1.44 mm

Clamping

Shrink chuck for precise concentricity

Coolant

Emulsion between 7-9%

Tool life

An impressive tool life of around 2,000 minutes was achieved during roughing on the very first use. The blunt milling cutter was reground and recoated at the factory, after which a tool life of around 1,700 minutes was achieved again.

Benefits at a glance

- Long cutter service life: 3,700 minutes total cutting time

- Significantly reduced tool costs

- High process reliability: Stable and economical machining of large titanium components

- Problems with chip and heat formation completely solved

- Unmanned or autonomous production possible