Micro-component made of molybdenum - high-performance material for extreme requirements

As one of the most heat-resistant materials - with a melting point of over 2600 °C - pure molybdenum places the highest demands on machining. Read the following success story to find out how a micro-component made from this demanding material was successfully realized thanks to innovative tool technology and a reliable production strategy.

Special requirements for processing molybdenum

The production of current-conducting micro-components made of pure molybdenum requires maximum precision and process reliability. Manufactured on a Swiss-type lathe, the micro components undergo machining steps on both the main spindle (C1) and the counter spindle (C2). The selection of the right collets is the first hurdle - because it has a significant influence on the stability and repeatability of the entire production process.

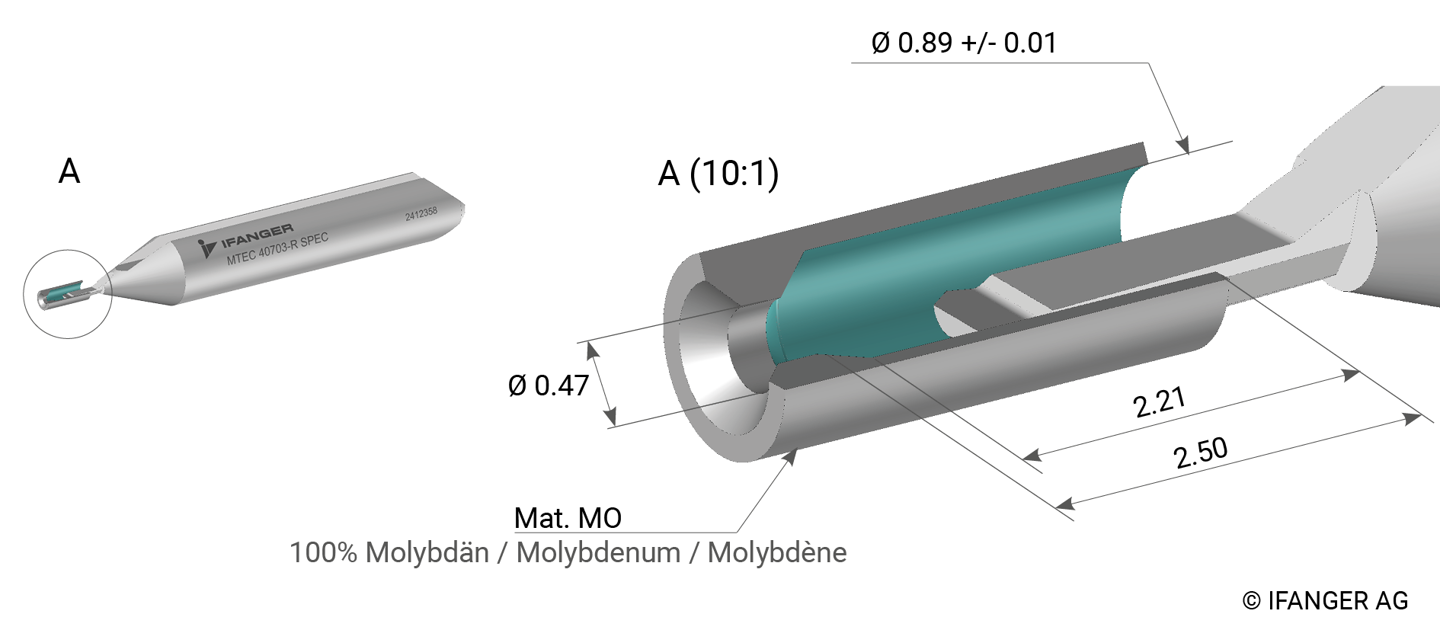

The internal turning of the guide bore with a diameter of just 0.89 mm, which has a tight tolerance over its entire length, is particularly challenging. The bore ends in a cone and the ratio of diameter to bore length is around 1:4 - a geometry that requires the use of long-necked and therefore delicate boring tools. These are particularly susceptible to vibrations during machining, which makes process stability even more difficult and significantly increases the risk of dimensional deviations and tool breakage.

Added to this are the material-related challenges: Molybdenum is one of the most heat-resistant and at the same time most brittle materials in the industry. Its high hardness, pronounced tendency to work harden and abrasive structure lead to exceptionally rapid tool wear - even with optimum cooling and cutting.

Solution

A specially developed Swiss MicroTurn MTEC 40703-R-TiAlN SPEC boring tool was used to produce the guide bore in molybdenum. The geometry of the tool (see illustration below) was specifically designed to ensure maximum rigidity - crucial for minimizing vibrations and preventing tool breakage. Tool radii, rake angles, clearance angles and the TiAlN coating were precisely matched to the machining properties of molybdenum. The result: stable cutting conditions, high dimensional accuracy and a significantly longer tool life - the best compared to all tools used.