When every second counts!

Maximum efficiency and precision in internal machining. Innovative machining strategies significantly increase productivity and optimize processes. Discover new possibilities for economical production!

The challenge

In certain situations, it is necessary to carry out the internal profil machining of a turned part with just a single tool. This may be necessary, for example, if there are minimum cycle times, limited tool positions or special machining requirements.

Practical example

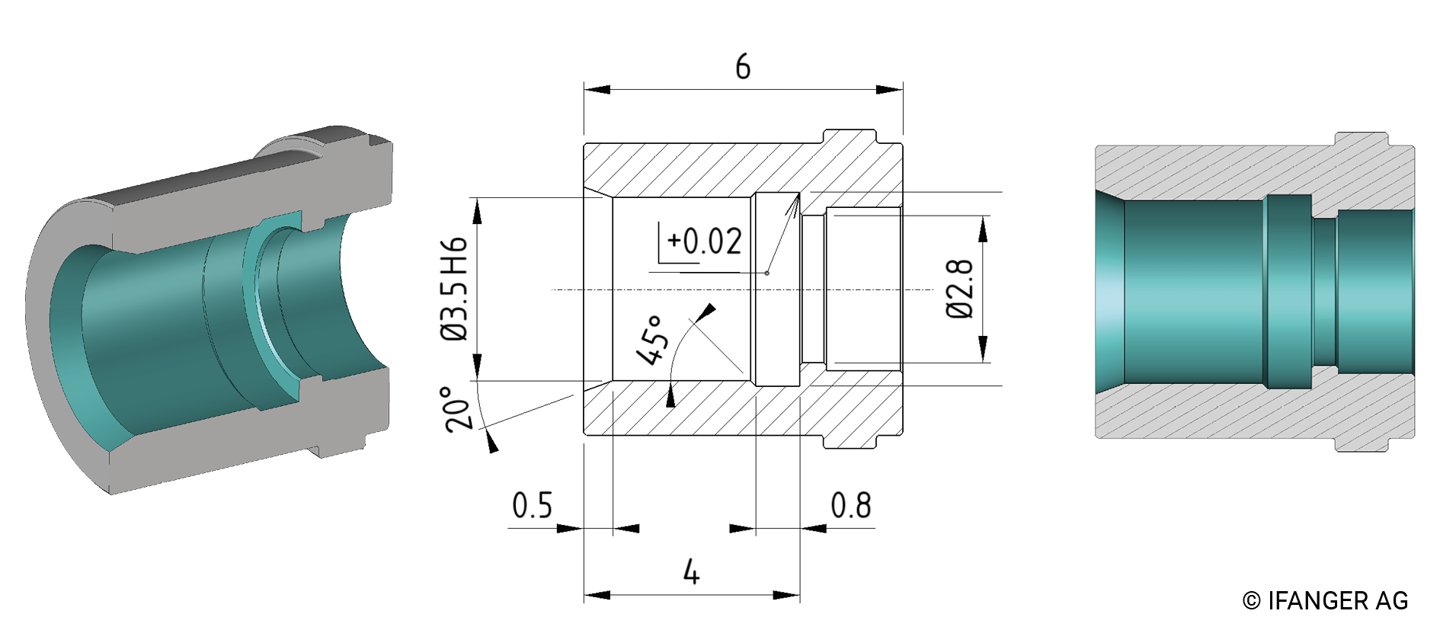

The workpiece shown below with tight tolerances is manufactured on a rotary transfer machine. Due to the short cycle times, a tool change during internal contour machining is not possible. A tool is therefore required that can perform both roughing and finish machining of the contour - including chamfers, precise holes and recesses.

Solution

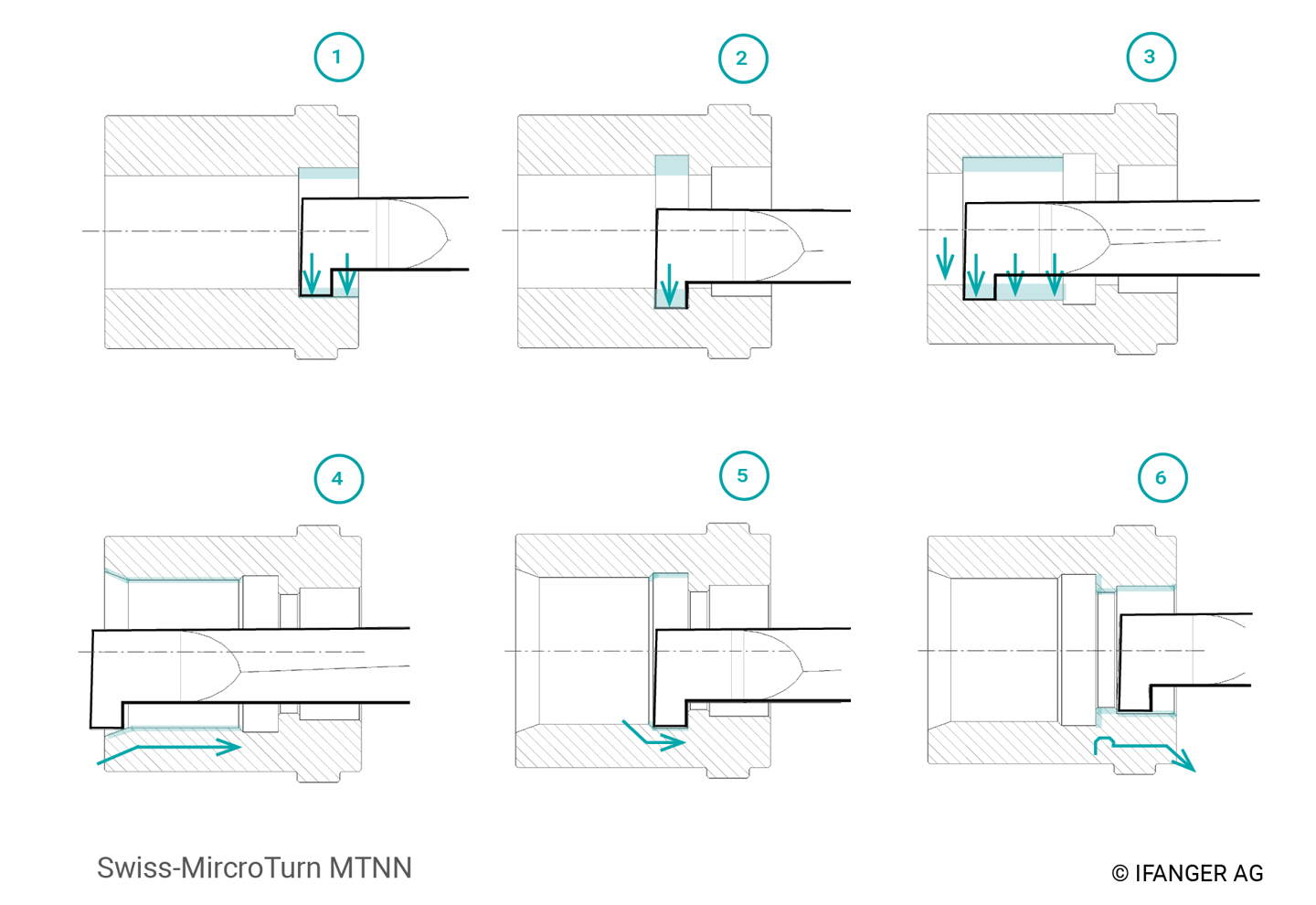

MTKR reverse copying steels from Ifanger's Swiss MicroTurn line are the first choice for classic reverse machining. If additional grooves need to be made, the MTNN family of grooving steels is the ideal choice - ideal for precise and reliable internal machining. This is illustrated in the figure below.

Thanks to their sharp cutting edges and generous clearance angles, MTNN grooving steels enable efficient machining, even with backward movements. They are also particularly suitable for producing angular grooves. Tool radii, rake and clearance angles, tool neck lengths and coatings can be adapted to specific material requirements or complex workpiece geometries on request. If there is an increased risk of breakage, the carbide composition or the substrate can also be specifically modified.

Machining strategy

The workpiece is first pre-drilled to a diameter of 2.6 mm. Pre-roughing is then carried out with the MTNN grooving tool by successive radial grooving along the axis (Fig. 1 - 3) - starting at the front and ending at the rear of the component. The finishing pass is then carried out in a backward motion (Fig. 4 - 6) to ensure precise and clean finishing.