CBN - inspired by diamonds

Cubic boron nitride (CBN) is considered as a milestone in the cutting technology. CBN is the second hardest known cutting material after diamond. It is characterized by exceptional hardness, high wear resistance and outstanding resistance to heat and chemical stress. This makes it ideal for machining very hard ferrous materials and superalloys, where other cutting materials quickly reach their limits.

Performance characteristics of CBN for machining

1. extreme wear resistance

CBN is characterized by excellent resistance to abrasive wear, which leads to significantly longer tool life, especially with hard materials such as hardened steel or superalloys.

2. thermal stability

CBN retains its hardness even at temperatures of up to 1200°C, which is crucial for high-speed and dry cutting.

3. chemical stability

Chemically inert to ferrous materials, so no the same interactions as with diamond.

4. excellent surface finish

Precise machining with CBN enables excellent surface qualities and maintains tight tolerances.

Application examples for CBN tools

1. hardened steel

CBN tools are used in automotive and mold making for machining highly hardened, heat-treated steels. CBN tools can be used to machine hardened workpieces directly on the lathe - an economical alternative to cylindrical grinding

2. high-temperature alloys

In the aerospace industry, CBN tools prove their strength in the high-precision machining of demanding nickel- and cobalt-based high-temperature alloys.

3. powder metallurgical materials

For the machining of powder metallurgical parts.

Working with the right material: CBN or diamond?

| Criterion | CBN tools | Diamond tools |

| Material types | Hardened steel (>50 HRC), sintered steel, hard ferrous materials | Non-ferrous metals, composite materials (fiber-reinforced) |

| Chemical stability | Very stable against iron | Reacts with iron at high temperatures, therefore unsuitable for steels |

| Temperature resistance | Up to approx. 1200 °C | Loss of hardness from approx. 700 °C |

| Economic efficiency | Longer tool life for ferrous materials, fewer tool changes | Effective with abrasive, non-ferrous materials |

Supplier of CBN turning tools

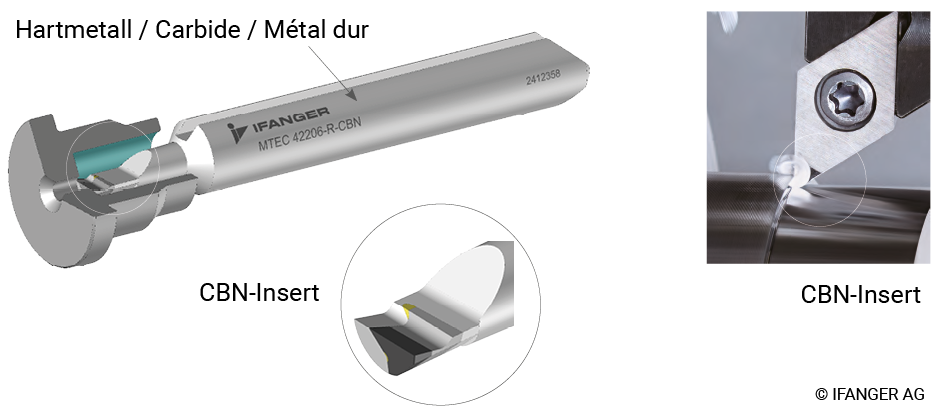

Due to their size, indexable inserts can no longer be used for small bore diameters. In such cases, monoblock tools are used, in which a CBN insert is brazed onto a carbide body.

CBN internal turning tools from IFANGER

The new IFANGER CBN tools extend the proven Swiss-MicroTurn system and open up new possibilities in precision internal machining from 2 mm bore diameters. Individually adaptable cutting edge geometries guarantee maximum precision - Once again, IFANGER is promoting the swiss quality with maximum sharpness, stability and perfection.

Swiss-MicroTurn with CBN insert

Swiss-MicroTurn with CBN insert

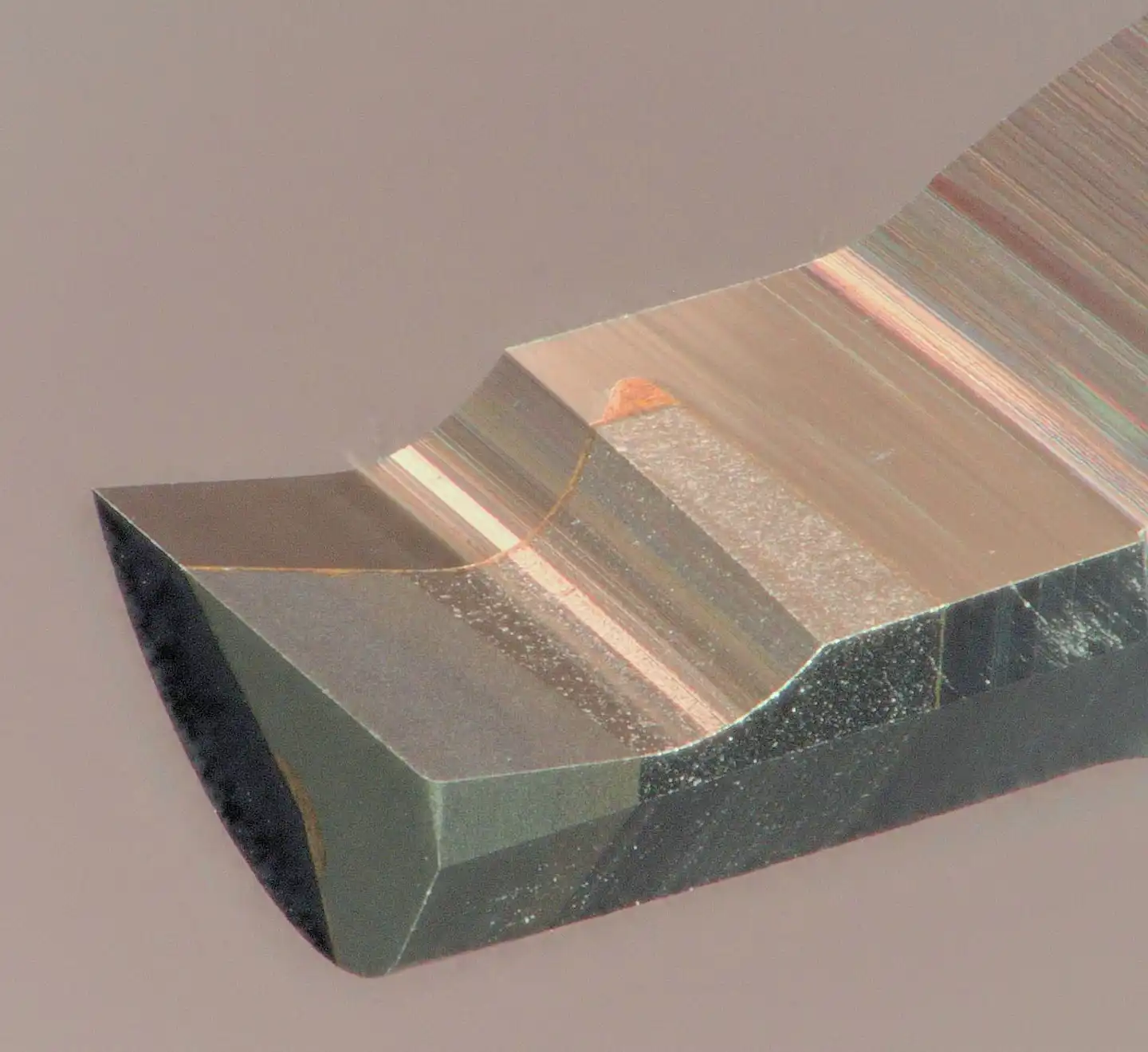

All-round ground CBN with sharp edges, the brazed joints are also ground on all sides

Customer feedback from the field

Outstanding performance in the machining of superalloys

A customer from the high-precision manufacturing sector reports: Thanks to the specific positive cutting edge geometry of our CBN tools, the tool life was doubled compared to a competitor's product. The clean processing of the solder joints avoids chips adherence on the tool - a decisive advantage for stable processes and long tool life. The result: 100% more parts can be produced unmanned after work - with maximum precision and reliability.